XMK design WS series unit cooler is using water defrosting method , the defrosting time is short, and the little effect on cold room temperature. Sieve poretype defrosting water pan and inner & outer water baffles are used to prevent water spraying into cold storage and wind blades during defrosting.

Efficient recirculating and Low Consumption are product feature.

Item NO.:

WS133/263LPayment:

T/TProduct Origin:

ChinaColor:

whiteShipping Port:

GuangzhouProduct Description

Casing

Adopt high quality steel plate with powder coating RAL9003

Heat exchanger coil

Copper tubing φ15,spacing 50 x 50 . Corrugated aluminium fins, fin spacing 4.2 mm & 6.4 mm.

Refrigerants

It can meet requirements of R404A, R507A,R448A,R449A,R134a,R22 and other refrigerants.

Fans

External rotor motor with high wind pressure, working temperature -40°C ~ 60°C

High air duct design with Integral stretching , good ventilation effect, further airthrow , lower noise. Fans individually connected to junction box.

Fan blade φ400, φ500, φ630, standard 4-pole motor.

Specification

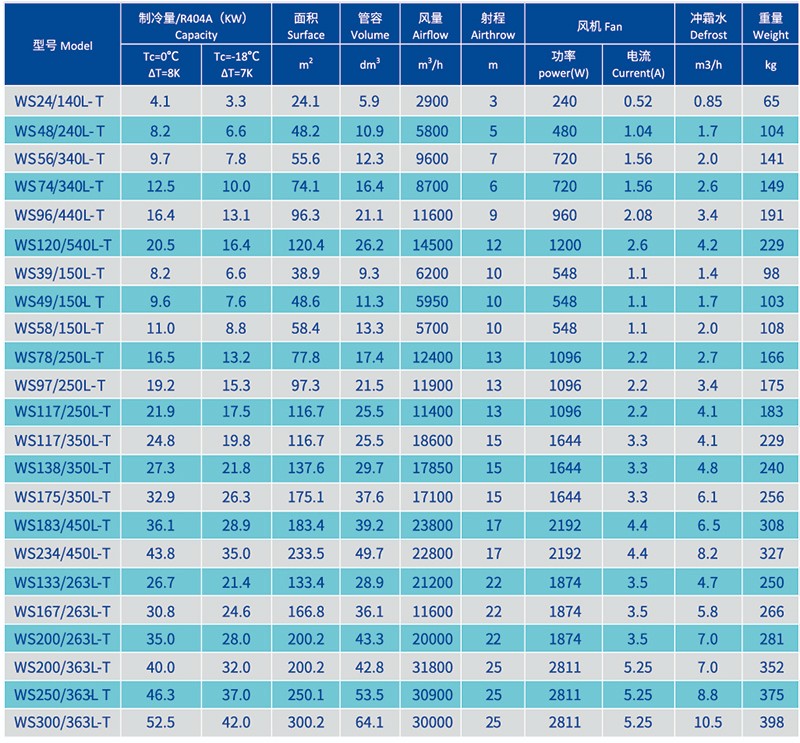

Water defrosting unit cooler model in fin spacing 6.4mm ,Capactity support 4KW to 52.5KW

Related Tags :